- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

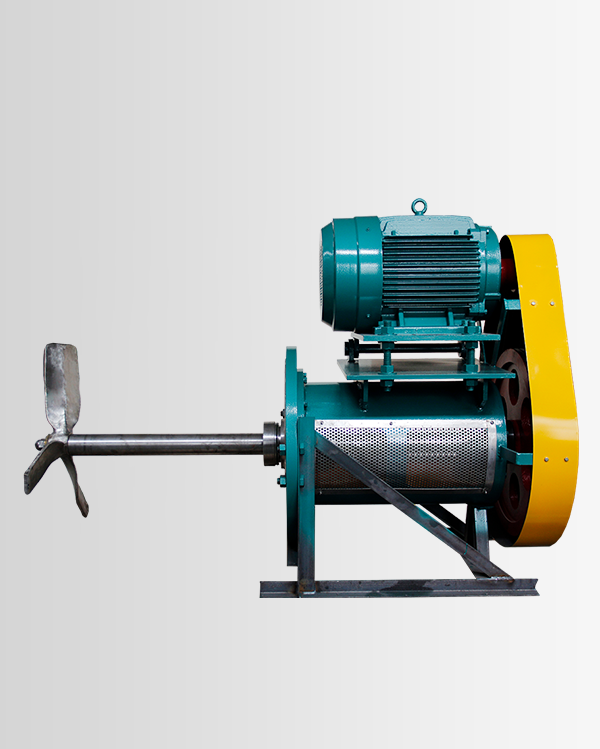

Keheng FGD Side Entry Mixer

In the pursuit of cleaner air and environmental sustainability, industries worldwide are increasingly turning to flue gas desulfurization (FGD) systems to mitigate harmful emissions. These systems play a critical role in removing sulfur dioxide (SO2) from exhaust gases produced by industrial processes, particularly in power plants and refineries. Central to the efficiency and effectiveness of FGD systems is the proper mixing of reagents with flue gas, a task facilitated by specialized equipment such as side entry tank mixers.

The Role of Side Entry Tank Mixers:

Efficient mixing of the flue gas with reagents is crucial for achieving high removal efficiency in FGD systems. Side entry tank mixers are specifically designed for this purpose, offering several advantages over other mixing methods:

Uniform Distribution: Side entry tank mixers ensure thorough mixing by dispersing reagents evenly throughout the flue gas, promoting maximum contact and reaction efficiency.

Reduced Maintenance: With their robust design and placement outside the reaction vessel, side entry mixers minimize maintenance requirements and downtime, enhancing system reliability and longevity.

Flexibility: These mixers can be easily installed or retrofitted into existing FGD systems, providing a cost-effective solution for improving performance without significant infrastructure modifications.

Energy Efficiency: By optimizing mixing efficiency, side entry tank mixers help reduce energy consumption associated with the FGD process, contributing to overall operational cost savings and environmental sustainability.

As industries continue to prioritize environmental stewardship and regulatory compliance, the demand for effective flue gas desulfurization solutions remains high.

Side entry tank mixers play a vital role in optimizing the performance and efficiency of FGD systems, facilitating the removal of sulfur dioxide and other harmful emissions from industrial exhaust gases. By partnering with a reputable manufacturer and investing in high-quality mixing equipment, industries can achieve cleaner air, reduced environmental impact, and sustainable operations for years to come.

Product Quality

All of our mixers are manufactured in specialized custom-built facilities to ISO9001 quality standards and used only high quality components in their construction.

Custom Design

Our professional technical team will design the most suitable mixer according to your requirement, which can achieve maximum value in use.

Project Management

We assign dedicated project managers to ensure that every aspect of manufacturing,assembly and quality control is progressed to meet individual customer specifications.

Customer Service

All KEHENG customers will get support and suggestions before and after sales. We help customers use product correctly: PLAN、INSTALLATION、TRAINING、TROUBLE REMOVAL、MAINTENANCE AND REPAIRS、RENOVATION AND MODERMIZATION.

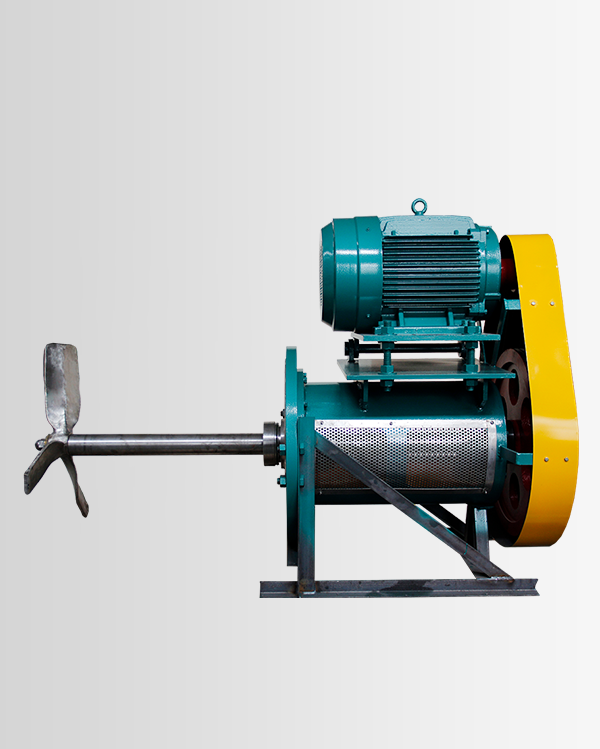

Keheng FGD Side Entry Mixer

In the pursuit of cleaner air and environmental sustainability, industries worldwide are increasingly turning to flue gas desulfurization (FGD) systems to mitigate harmful emissions. These systems play a critical role in removing sulfur dioxide (SO2) from exhaust gases produced by industrial processes, particularly in power plants and refineries. Central to the efficiency and effectiveness of FGD systems is the proper mixing of reagents with flue gas, a task facilitated by specialized equipment such as side entry tank mixers.

The Role of Side Entry Tank Mixers:

Efficient mixing of the flue gas with reagents is crucial for achieving high removal efficiency in FGD systems. Side entry tank mixers are specifically designed for this purpose, offering several advantages over other mixing methods:

Uniform Distribution: Side entry tank mixers ensure thorough mixing by dispersing reagents evenly throughout the flue gas, promoting maximum contact and reaction efficiency.

Reduced Maintenance: With their robust design and placement outside the reaction vessel, side entry mixers minimize maintenance requirements and downtime, enhancing system reliability and longevity.

Flexibility: These mixers can be easily installed or retrofitted into existing FGD systems, providing a cost-effective solution for improving performance without significant infrastructure modifications.

Energy Efficiency: By optimizing mixing efficiency, side entry tank mixers help reduce energy consumption associated with the FGD process, contributing to overall operational cost savings and environmental sustainability.

As industries continue to prioritize environmental stewardship and regulatory compliance, the demand for effective flue gas desulfurization solutions remains high.

Side entry tank mixers play a vital role in optimizing the performance and efficiency of FGD systems, facilitating the removal of sulfur dioxide and other harmful emissions from industrial exhaust gases. By partnering with a reputable manufacturer and investing in high-quality mixing equipment, industries can achieve cleaner air, reduced environmental impact, and sustainable operations for years to come.

Product Quality

All of our mixers are manufactured in specialized custom-built facilities to ISO9001 quality standards and used only high quality components in their construction.

Custom Design

Our professional technical team will design the most suitable mixer according to your requirement, which can achieve maximum value in use.

Project Management

We assign dedicated project managers to ensure that every aspect of manufacturing,assembly and quality control is progressed to meet individual customer specifications.

Customer Service

All KEHENG customers will get support and suggestions before and after sales. We help customers use product correctly: PLAN、INSTALLATION、TRAINING、TROUBLE REMOVAL、MAINTENANCE AND REPAIRS、RENOVATION AND MODERMIZATION.